You can use any saw with fine teeth for cutting the fret slots. The

slots will be filled with veneer strips later, so make sure to have

veneer that fits tightly into the slots cut with the saw. Also note

that the thickness of a saw blade is usually smaller than its width

of cut. This is because most saws have set teeth, which means that

they are slightly bent to the left or right. If your saw has a

width of cut of 1mm, use veneer of 1mm thickness. Because I wanted

quite narrow fret position markers, I used a saw with a width of

cut of 0.024" (0.6mm). I can recommend veneer 1/32" to

1/16" (1mm to 2mm) thick as it is much more stable. Cut the

fret slots to a depth of about 1/16" (2mm).

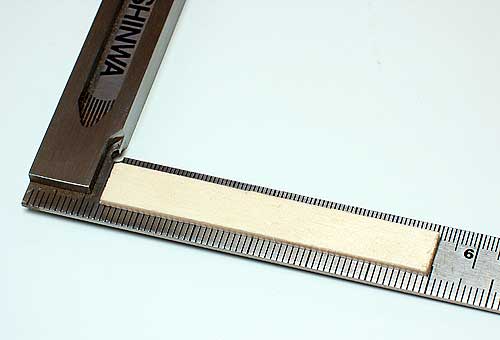

I attached a strip of wood to the underside of the square to ensure

that the square would touch the blade above the teeth of the saw.

This is more accurate and prevents the teeth from rubbing against

steel and thus dulling. When all the fret slots have been cut, they

are deepened to a uniform depth of 1/8" (3mm). Attach a strip

of wood to one side of the blade using doublefaced tape

(Haven't I mentioned yet that I love doublefaced

tape?). The strip is attached parallel to the cutting edge and at a

distance of 1/8" (3mm) from the tips of the saw teeth. This

simple depth stop ensures equal slot depth. Finally, cut through

the fretboard at the zerofret and the 25th fret.